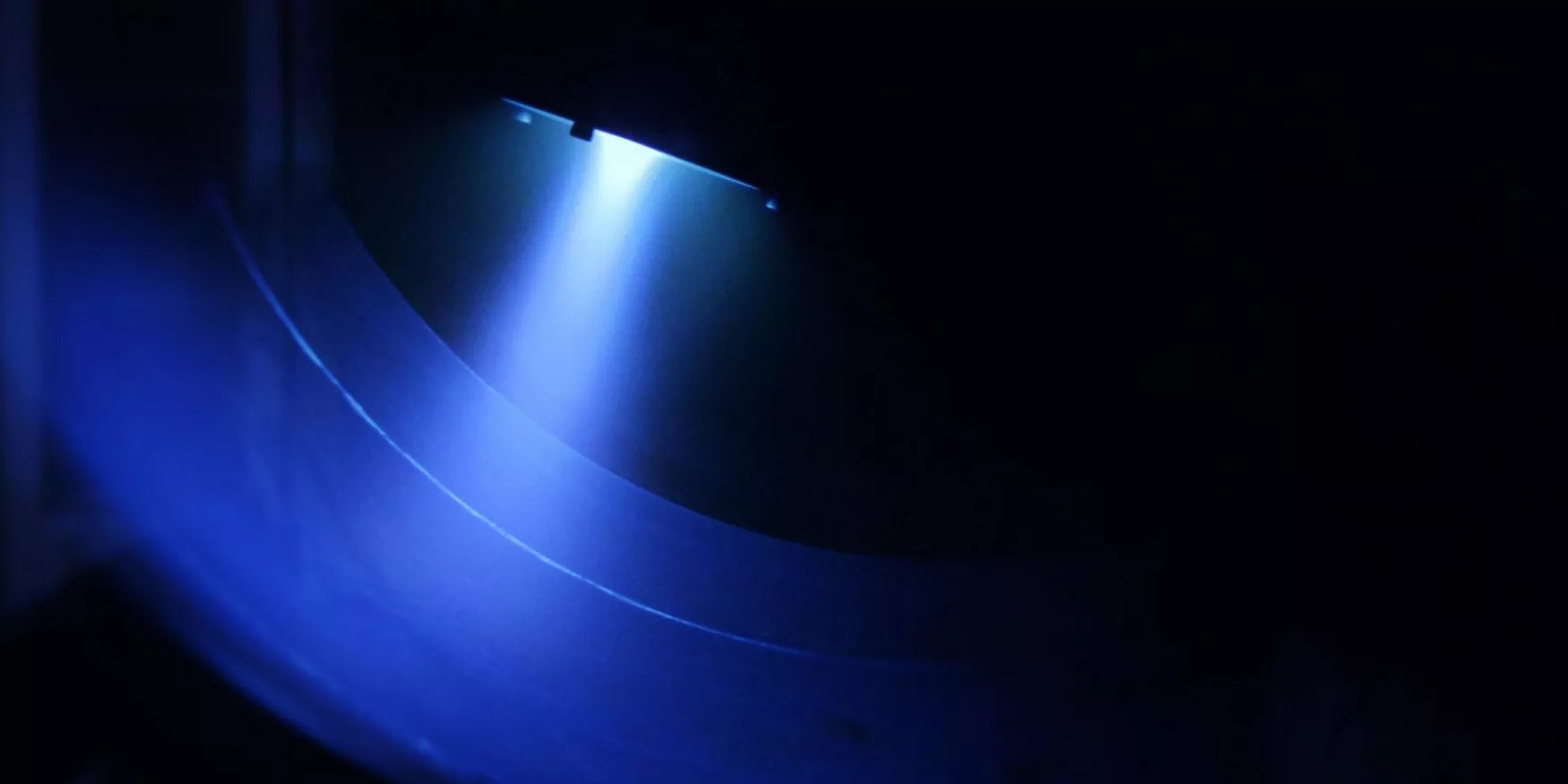

Vacuum Plasma Deposition PVD

PVD (vacuum vapor deposition) technologies make it possible to modify the surface of an object by adding a layer (thin and dense) or a stack of different types (metal, alloys, oxides, nitrides, carbides. ..) without touching the basic material. Thus an object or a part having undergone a surface treatment will for example have a different visual appearance from that which it had before or even chemical, mechanical, electrical, optical, magnetic, tribology surface properties different from the base material of which it is from.

Vacuum deposition consists of depositing a thin layer of another material (metal, ceramic, etc.) on a metallic or non-metallic object. This makes it possible to give the object new properties for surface protection (chemical and mechanical), modification of tribological properties, control of interactions with the environment (adhesion, chemical affinities, surface energy) or for aesthetic reasons. .

PVD stands for “Physical Vapor Deposition”, this means that the deposition process takes place without a chemical reaction by transport of the metal which has previously been transformed into the vapor phase from a source and which comes condense or settle on the part to be covered through plasma physical phenomena.

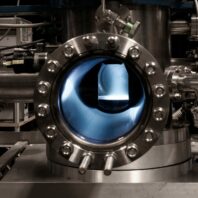

PVD vacuum deposition brings together several techniques, one of which is quite widely used in the industrial world and at Materia Nova which is called: “magnetron cathode sputtering” or “cathodic magnetron sputtering” in English.

Vacuum deposition applications are an integral part of our lives, we find them in the electronic, optical, mechanical, decorative industries, etc.

The subjects developed by this technology at Materia Nova are:

- Protective coatings (Anti-corrosion, Wear resistance, UV resistance, Hard coatings, Tribological films, etc.)

- Functional coatings (Antimicrobial surfaces, Optical properties, Easy to clean, TCO and conductive coatings, Hydrophobic, Hydrophilic, Barrier effect (gas, water, etc.), Energy management, etc.)

- Active coatings (Sensors, Catalysis, etc.)

- Etc …

Our strengths :

- Materia Nova now offers access to PVD systems from laboratory scale to semi-industrial pilot scale and proposes the development of tailor-made coating solutions or processes to meet industrial challenges.

Our solutions for this technology

- Anti-friction and anti-noise coatings

- Sterilization

- Electrochemical storage batteries

- Fire resistance

- Surface (metallic and plastic) metallization

- Protection against corrosion

- Treatment of liquid effluents

- Antimicrobial properties

- Detection (sensor)

- Air purification

- Catalytic properties

- Outdoor resistance (atmospheric agents, UV, temperature, humidity, pollutants)

- Decontamination & Sterilization

- Resistance to friction, wear and tear, impact, scratch resistance

- Structuring and surface pattern

- Anti-adhesion, wettability and sliding

- Surface colouring