Reactive extrusion

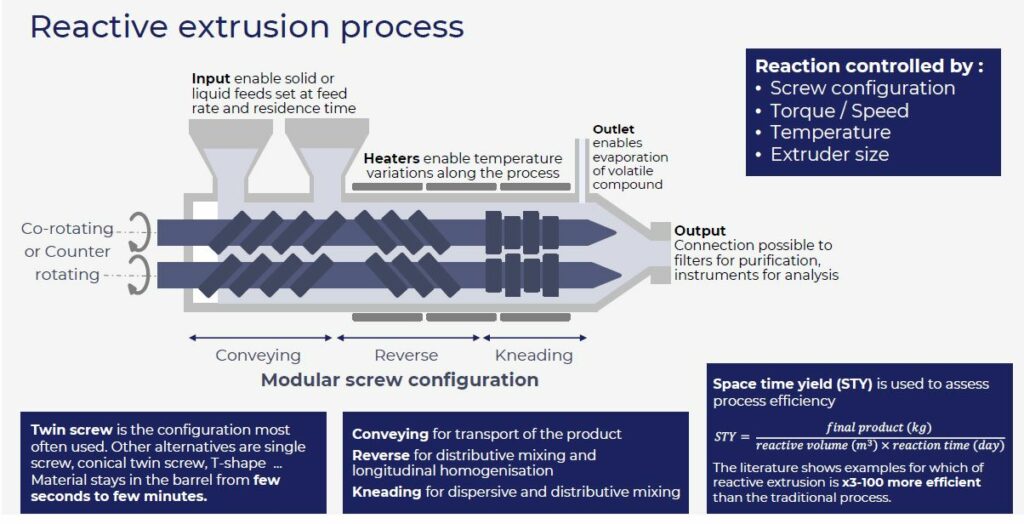

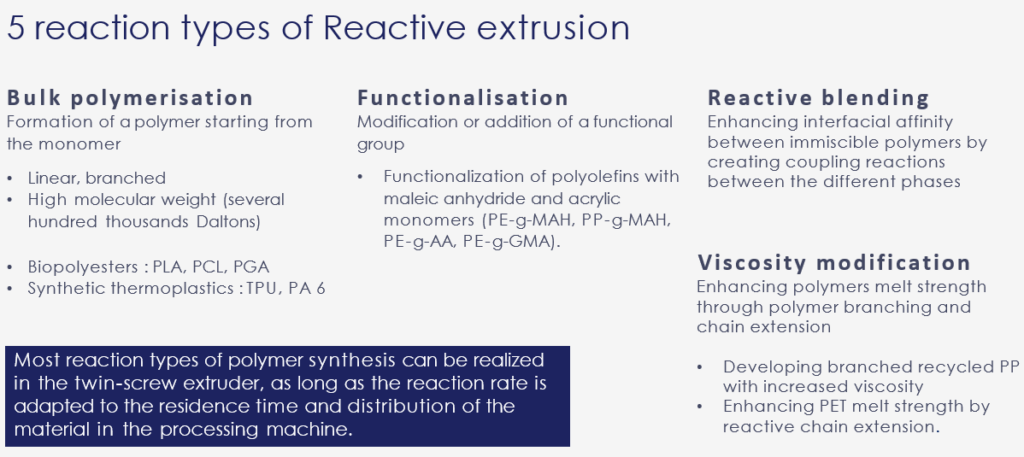

Reactive extrusion is a process that uses an extruder as a reactor to carry out chemical reactions, continuously and solvent-free.

At Materia Nova, this technology is used to chemically modify commercially available thermoplastics (polyolefins, polyesters...), natural biopolymers (starch, cellulose) or to prepare new (bio)polymers (PLA, NIPU...) to improve or optimize their performance.

Here are just a few examples:

- Improving the thermal resistance of PLA through the formation of stereocomplexes by polymerization of L and D-Lactide, in tandem configuration.

- Enhancing the ductility of PLA by grafting an innovative biobased plasticizer, an approach applicable to other biobased polymers such as starch.

- Optimization of the blend of bioplastics and glycerol-plasticized thermoplastic starch (TPS) by reactive extrusion.

Reactive extrusion is a synthesis route that enables us to consider several chemical reactions in succession, and to work on highly viscous media.

Our fleet of reactors and extruders enables us to carry out in-depth evaluations of both the processing and functional attributes of materials (even with just a few grams), and to produce polymer compounds, monolayers and films, as well as injection molding.

Our strengths:

- Materia Nova has developed strong expertise in reactive extrusion as a solvent-free method for synthesizing new polymers or modifying them.

- Materia Nova has an array of extruders adapted to reactive extrusion, which enables it to gradually scale up to carry out grafting, chain extension or polymerization reactions, on a few dozen grams, hundreds of grams to a few kilograms. These extruders are equipped with accessories that allow the dosing of different reagents in liquid or powder form.

- Thanks to its range of structural, thermal, morphological, mechanical, biodegradation, bio-resorption and fire analyses and characterizations, Materia Nova can cover the entire development chain for composites with one or more properties.