Electrospinning

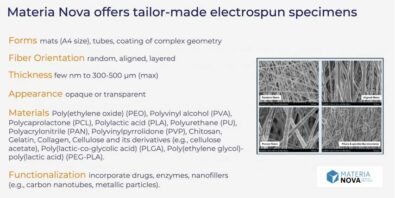

Electrospinning is a valuable technology for the production of polymer and polymer composites micro- and nanofibers. This simple and already industrialized method involves the application of a high electric voltage (up to 50 kV) to a polymer solution or melt.

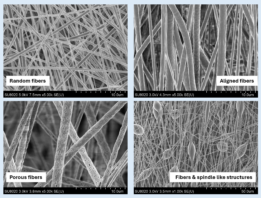

Upon the influence of the applied field strength, a repulsive electrostatic force overcomes the surface tension of the solution or the melt, and a charged jet is ejected from the capillary leading to the formation of dry micro- and nanofibers. Depending on the solutions or the melt composition and properties, the obtained non-woven fabrics can be made from fibers with interesting morphology: monolithic fibers, core-sheath or hollow, flat fibers, fibers with pores, and others. Working with low viscosity spinning solution or melt can allow the preparation of micro- and nanoparticles.

It is worth mentioning that electrospinning is a valuable approach allowing the development of fibers from initially immiscible polymers (e.g. water-insoluble and water-soluble polymers) by suitably adjusting the solvent mixture with adapted polarity or temperature range.

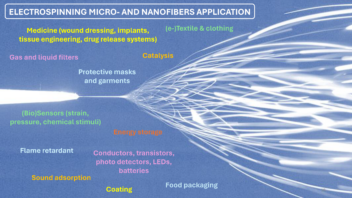

Due to the possibility to successfully incorporation of drugs, natural biomolecules, enzymes or nanofillers (carbon nanotubes, metallic particles…), the micro-and nanofibrous materials can find great range of applications in: medicine (wound dressing, implants, tissue engineering, drug release systems with antitumor, antibacterial and hemostatic properties), coatings, (bio)sensors (strain, pressure, chemical stimuli), gas and liquid filters, catalysis, (e-)textile and clothing, fertilizers, flame retardant, sound adsorption, food packaging, energy storage, conductors, transistors, photo detectors, LEDs, batteries and others.