Internal treatment of tubes and hollow objects

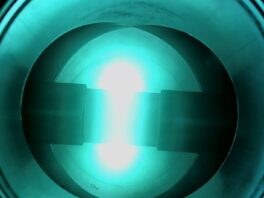

Treating the inside of very thin tubes requires a specialized and innovative approach to overcome technical challenges and guarantee efficient and uniform treatment.

Materia Nova has the technology required to process various types of tube (metal or glass) with diameters in excess of 4 cm. In addition, we have patented advanced technology (PVD or PECVD systems - mini-cathode) for processing hollow objects with smaller diameters (from 5 mm to 4 cm over a length of 1 meter).

This patented technology guarantees a uniform, precise coating over the entire inner surface and precise control of coating thickness. Finally, the method can be combined with additional pretreatment steps to further enhance coating properties. This flexibility enables further customization and optimization of coating properties for specific applications, making it a versatile and adaptable coating method.

Thanks to the various coatings available from Materia Nova, we can treat the inside of tubes according to the needs and requirements of our customers' specific applications:

- Protecting metal tubes against corrosion. Especially those used in corrosive environments (such as water, oil or chemical pipelines) can be treated to prevent internal corrosion.

- Improved wear resistance and particularly in applications where abrasive materials or fluids flow at high speed,

- Reduced friction. Internal coatings can reduce friction, improving the efficiency of fluid or gas flow through the tube,

- Temperature resistance, thermal and electrical insulation. Certain treatments can improve the tubes' resistance to extreme temperatures, enabling them to be used in high or low temperature applications, insulate to protect against temperature variations, or electrically insulate the tube's contents,

- Antimicrobial properties. In medical or food applications, antimicrobial treatments can be applied to prevent the growth of bacteria or other micro-organisms inside tubes.

- Improved chemical properties. Treatments can make tubes resistant to certain chemicals, which is essential for industrial applications where reactive substances are transported.

- Easy to clean. Non-stick coatings can facilitate tube cleaning, which is important in the food and pharmaceutical industries.

- Barrier properties and permeability reduction. It prevents contamination by volatile gases or liquids, guaranteeing purity and safety.