Functionalization and spheroidization of powders

The ABBEADS I and II technology developed by Materia Nova consists of vacuum plasma deposition using a rotating barrel system, capable of coating powders (ranging in size from microns to several millimeters) or small bulk parts thanks toa rotating barrel system.This so-called “cold” technology has the advantage of being able to treat any type of substrate that cannot heat up to more than 50°C (metals, polymers, ceramics).

It also makes it possible to deposit materials with very varied chemical compositions such as metals and their ceramic compounds (oxides, nitrides, carbides, etc.) but also polymers. The deposits made range from a few tens of nanometers to micrometers. The composition of the deposit and therefore of the powder after treatment can be adjusted in order to adjust the composition of the powder to the wishes of the end customer. In addition, it is possible to produce a deposit perfectly covering the surface of each grain constituting the powder (formation of a “core-shell) and to produce specialty alloys, to improve and intensify additive manufacturing processes. and, to provide certain functionalities. The prospects envisaged are the protection of powders (explosiveness, anti-oxidation) as well as the improvement of their flowability and their anti-clogging.

The applications of this technology are diverse in areas such as technical adhesives (conductive for example), catalysis, composite materials, sintering, thermal spraying, etc. as well obviously as in additive manufacturing.

As part of the development of new materials from the circular economy of metals in Wallonia (REMADE project Public Service of Wallonia Pôle MecaTech), Materia Nova has added new equipment for the spheroidization of powders: TEKSPHERO-15 which uses a plasma torch inductively coupled. This system makes it possible to meet the expectations of our industries for more efficient powders:

✨ Better flowability for regular flow without clogging or operation of powder feeding devices (high level of sphericity and controlled particle size).

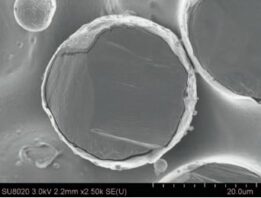

🔩 Increase in density (apparent and typed) or reduction in porosity (or gas inclusion) for demanding applications.

🔬 elimination of satellites, hollow or fractured particles to limit wear on transport pipes and increase the quality of the products used.

These high-quality metal powders are compatible with the most demanding industrial processes: Metal Injection Molding (MIM: Metal Injection Molding), Additive Manufacturing (AM: Additive Manufacturing), Thermal Spraying and Hot Isostatic Compression (HIP: Hot Isostatic Pressing). Versatile and scalable, the system allows you to develop the most sensitive metal powders or alloys (e.g. Al and Ti) but also ceramics in a neutral or reactive atmosphere (Ar, N2, O2, H2, etc.) for sizes varying from 5 to more than 200 μm.