An innovative titanium coating on Alu7075: a revolution for additive manufacturing

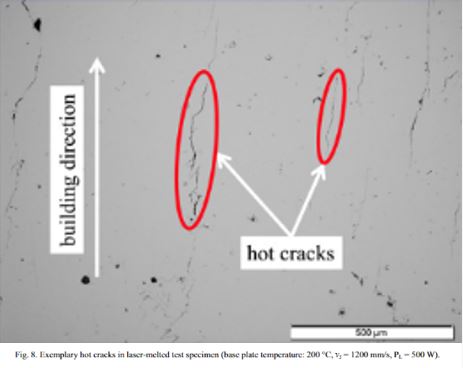

The 7075 aluminium alloy is known for its high mechanical strength, making it a popular material for high performance applications. However, its use in PBF_LB (laser-based powder bed fusion) additive manufacturing processes is limited due to its sensitivity to hot cracking.

Other high-performance alloys of the 7000 and 6000 series have similar problems.

__________________________________

__________________________________

Source of the problem

• Alloys such as Al7075 have a large solidification interval, unlike typical additive manufacturing alloys like AlSi10Mg, which solidify over a narrow interval.

• This wide solidification range promotes the formation of elongated dendrites, which trap liquid in the microstructure, leading to cracks.

• A narrow solidification interval (ex: AlSi10Mg) allows the formation of small dendrites that avoid this phenomenon.

__________________________________

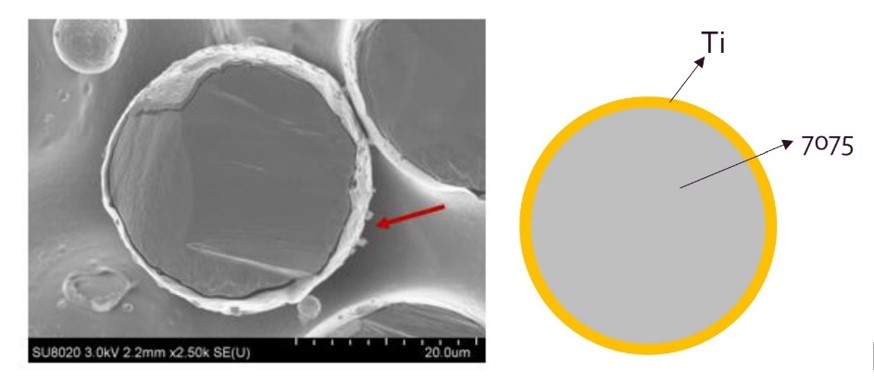

Innovative solution: titanium coating

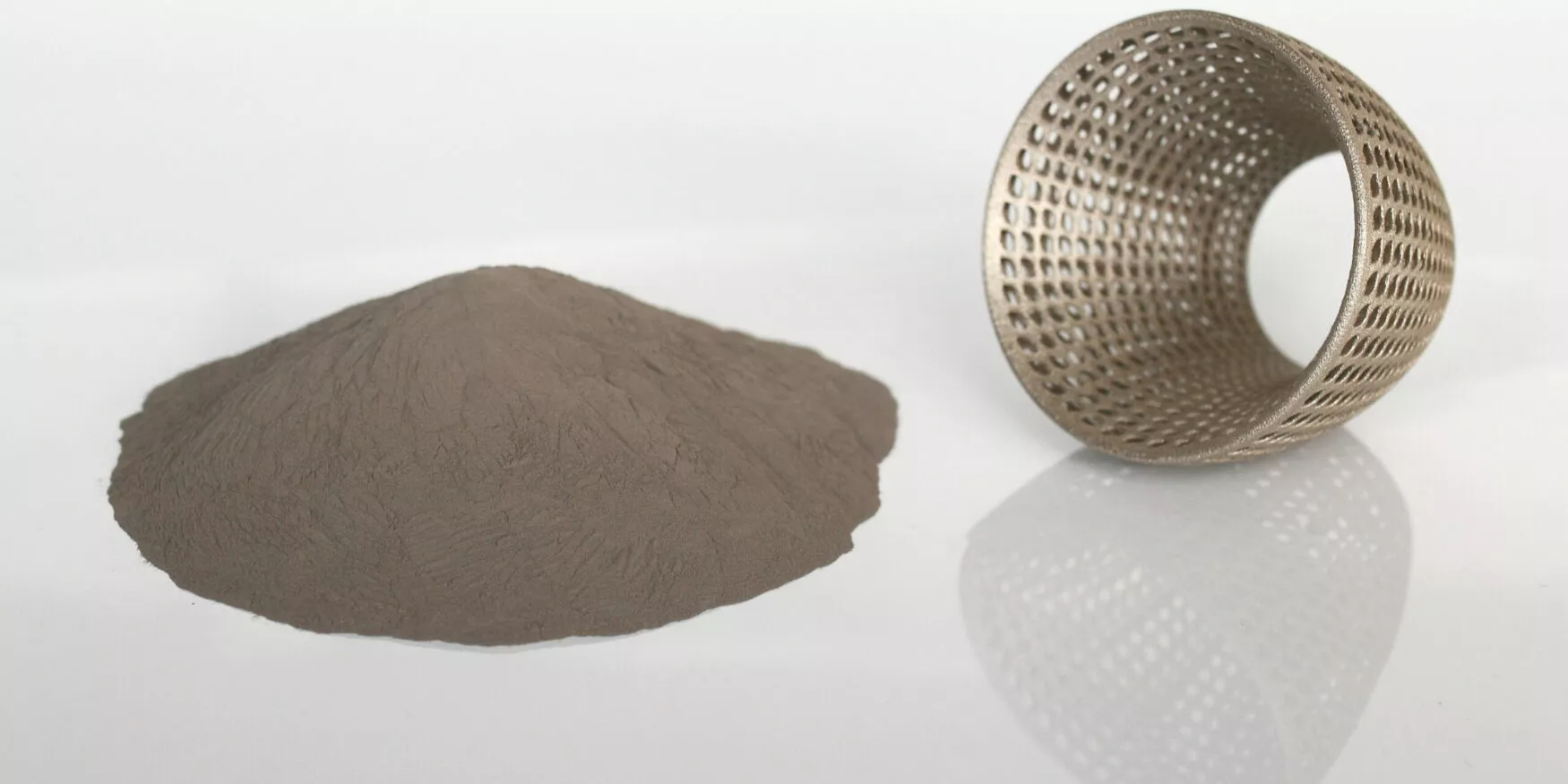

The modified Al7075 powder is coated with titanium (Ti), modifying the surface chemistry and acting as a cracking inhibitor by promoting the formation of nucleation sites.

This new alloy, called M7075, offers outstanding performance in LPBF additive manufacturing, especially in terms of microstructure.

💡 This process is patented under WO2025002659A1 by Sirris and Materia Nova.

________________________________________

Results obtained with M7075 powder

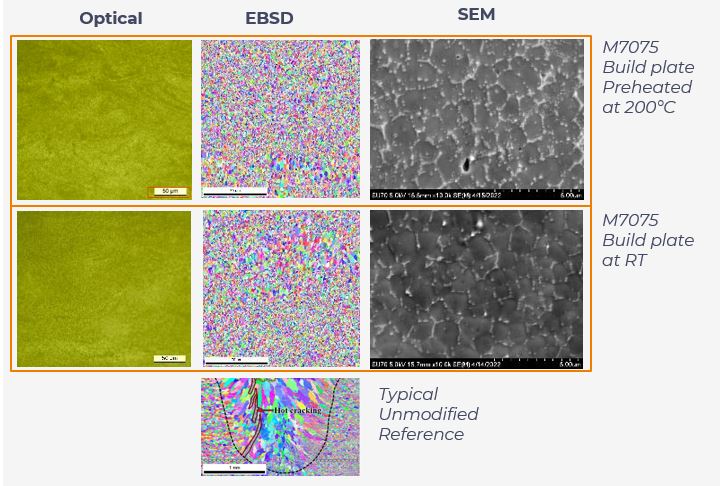

✅Optimized microstructure

✅No cracks, even without heating plate

✅High manufacturing density (>99.5%, without porosity)

________________________________________

________________________________________

Advantages of the M7075 over existing solutions

Benefits of the alloy

✔Composition close to the 7075 standards, facilitating its adoption

✔Without noble or exotic elements (Ag, Sc, Y...)

✔Does not rely on (nano) particles, guaranteeing homogeneous dispersion

✔Safe and non-toxic

Process benefits

✔Good compromise strength-ductility (robust and adaptable material)

✔ Compatible with known thermal treatments

✔Possibility of revaluing existing 7075 aluminum

✔Absence of ceramics, facilitating post-processing and machining

✔Compatible with anodizing (*)

________________________________________

This breakthrough opens new perspectives for the use of high-performance aluminum in additive manufacturing, making the 7075 finally 3D printable without compromise on mechanical quality.

Test the M7075 Powder Today!

You want to test our M7075 powder and discover its performance in additive manufacturing? Contact us now to find out more and arrange your first tests.

📩Thomas.Godfroid@materianova.be