PONAMP

Start of the project: 01-09-2019

End of project: 28-02-2022

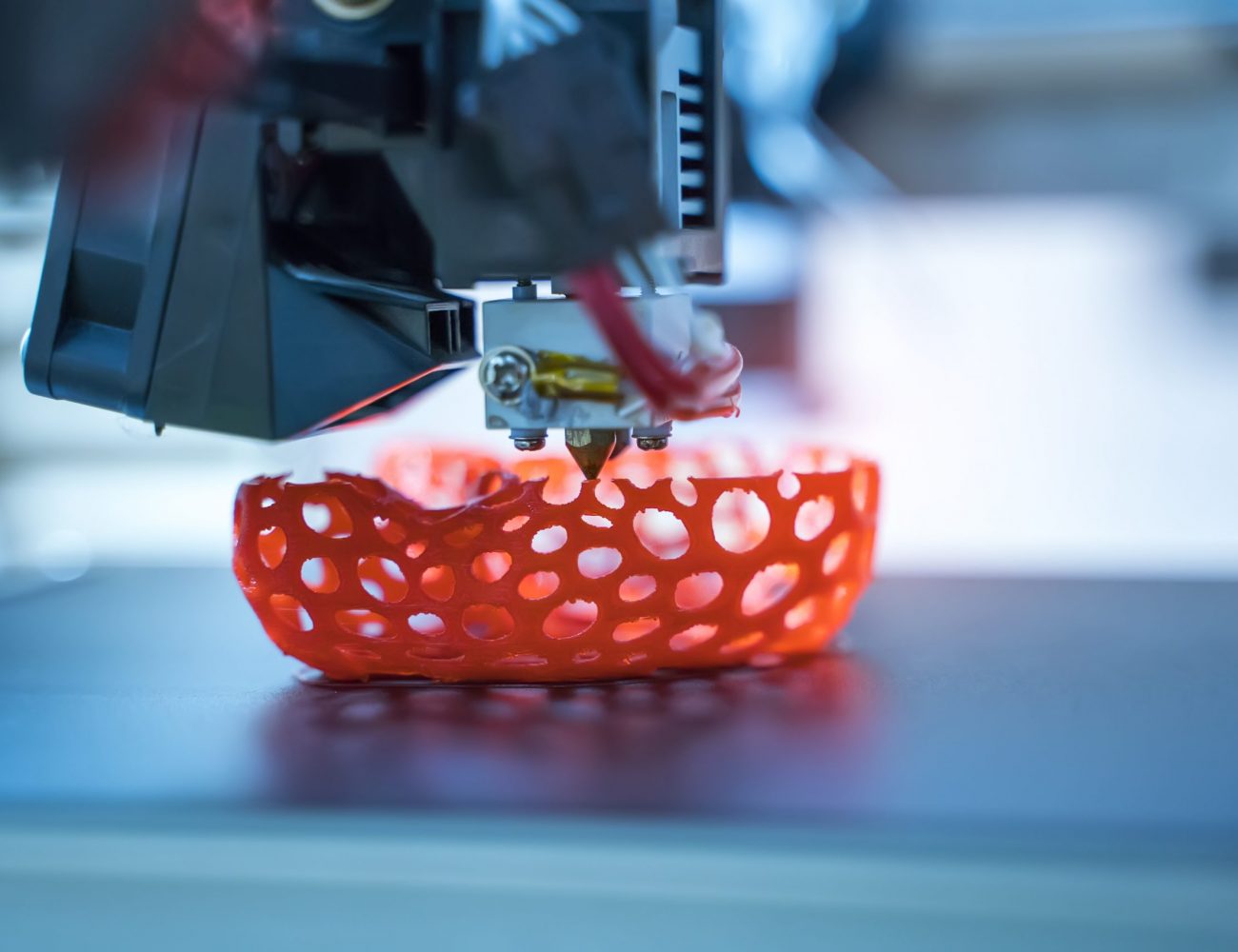

The PONAMP project focuses on the development of new materials for additive techniques based on powder bed fusion, leading to parts with improved properties. Today, a limited number of metal alloys are qualified for additive manufacturing, yet industrial demands are increasingly turning towards materials with superior properties, for broader, higher value-added applications. The approach in this project is to combine an existing alloy in powder form with another material added as a thin surface coating, which will mix during the additive process to counter the problems encountered with traditional alloys. Two aspects will be studied: high-strength aluminum alloys, and copper and copper alloys for their electrical properties. The manufacture of demonstrators in each of the 2 materials is scheduled for the end of the project.

These solutions will be tested in terms of their mechanical, physical and economic viability, in order to broaden the range of copper- and aluminum-based materials available for the various AM techniques, and to guarantee the durability of the proposed

technological solutions. In this context, the Walloon partners will optimize the process on several levels.

Materia Nova's objectives and missions

As part of the consortium, Materia Nova will carry out hot cathode magnetron sputtering surface treatments on the target powders (Al and Cu base). The development of homogeneous surface or partial encapsulation with different materials will optimize the powders and make the target alloys suitable for AM melting techniques.

Consortium partners:

Forschungsinstitut edelmetalle + metallchemie (FEM), Fraunhofer UMSICHT, Materia Nova, Sirris and Umons.