ACHEVALD

Start of the project: 01-04-2024

End of project: 31-03-2028

The aim of the Achevald project is to encourage manufacturers to replace the hard chromium (or hexavalent) plating technique in sectors such as metallurgy, automotive, aerospace, shipbuilding and nuclear power, which supply equipment that has to withstand increasingly severe constraints, while complying with ever stricter environmental regulations.

One of the technologies most affected by these regulations is hard chromium plating (or hexavalent chromium plating). Used in many applications, this surface coating technique makes it possible to produce wear- and corrosion-resistant coatings at reasonable cost. However, hexavalent chromium is classified as carcinogenic and harmful to the environment.

The ACHEVALD project will give companies the opportunity to test a panel of 4 alternative solutions to hexavalent chromium directly at the project partners' sites. The proposed technologies should make it possible to repair a worn part, or to confer locally on the functional surfaces of new parts, a better resistance to wear and corrosion than that of the body of the part.

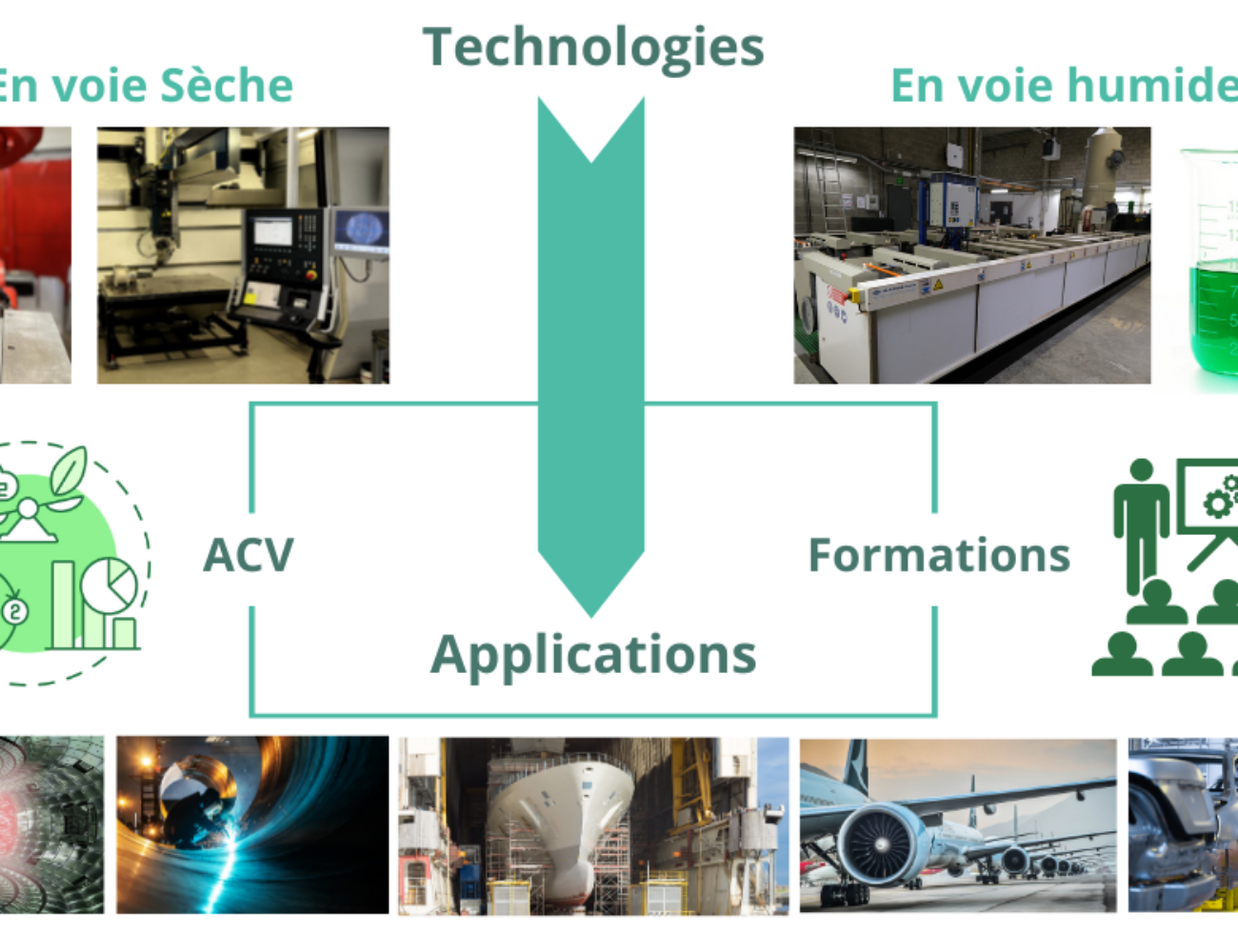

These solutions are grouped into 2 technological categories:

1.Wet deposition: chemical and electrolytic deposition

Wet process technologies are used to create coatings from a nickel matrix.

The ACHEVALD project will propose to innovate these coatings by including hard and/or self-lubricating particles, making it possible to improve the mechanical properties while retaining the anti-corrosion properties, without going through an energy-intensive post-treatment.

- UMONS will apply chemical nickel-boron coatings free of heavy metals and will carry out tribological, tribocorrosion, mechanical and chemical characterisations for all the partners.

- MATERIA NOVA will carry out the electroplating of composite coatings consisting of a nickel or nickel alloy matrix in which hard and/or self-lubricating particles are embedded. It will participate in the characterisation of corrosion by salt spray tests and also by electrochemical measurements of the deposits of all the partners.

2.Dry deposition: plasma and laser thermal spray deposition

Dry process technologies are welding-based cladding techniques.

At present, there are no clear studies or applications in the literature combining these two processes for chromium deposition and also showing their complementarity.

The ACHEVALD project will propose an innovative coating to meet industrial needs.

PLATINIUM 3D will contribute its expertise in laser cladding, depositing different materials on different substrates using different DED processes. Platinium will also be in charge of the needs analysis.

CRITT will focus on improving existing chromium deposits by PTA to try and increase their properties, as well as on different substrates. It will contribute to the chemical (SEM/EDX, DRX), mechanical (durometer) and structural (digital microscope, micrographic analysis) characterisation of the deposits of the entire consortium.

DCX Chrome will supply and improve its chromium powder for dry process testing.

These technologies will meet the needs of companies using tools that are subject to very severe constraints (temperature, stress, wear, fatigue, etc.).

In addition to technical support, the project will provide companies with theoretical and practical training on the 4 solutions made available to them, the characterisation equipment and the LCA study.

The project partners will provide 4 joint training courses (1 per year), with a minimum of 2 sessions per course. This will enable the project to be communicated in an educational way, targeting a wide audience (industry and students). The project will also provide industry with advice, support for implementation, technology monitoring and state-of-the-art studies.

The ACHEVALD project will develop environmentally-friendly surface treatments, by developing sustainable alternatives to hard chrome. It will contribute fully to the Green Pact strategy and its zero pollution ambition.

The Life Cycle Assessment (LCA) study that will be carried out as part of the project will make it possible to assess the environmental performance of the hexavalent chromium replacement treatments proposed in the project. This LCA will also help to guide and optimise the proposed alternative solutions so that they adhere as closely as possible to the principles of the circular economy, which aim to reduce waste, promote recycling and encourage the efficient use of resources.