Small series electrolytic/electroless deposits and bath validation

Materia Nova is equipped with two Electrolytic/Electroless Pilot Lines for small batch processing.

These lines are available to bath formulators and companies active in the field of surface treatment and/or metallization, and connector technology, seeking to:

- independent resources of technical experts,

- maintain their industrial production without interruption or slowdown,

- selective treatments,

- test and compare different baths under comparable, objective conditions,

- develop new, more efficient and environmentally-friendly baths,

- solve problems, optimize and stabilize the production process,

- train their staff in both theory and practice,

- characterize the performance of treated surfaces thanks to a wide range of analysis and characterization equipment (anti-corrosion properties, wear resistance, hardness, electrical conductivity, sweat resistance, UV resistance, etc.).

the two pilot lines:

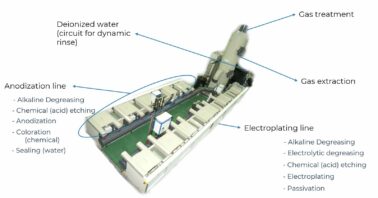

1/Pilot line (electroplating and anodizing of aluminum)

- Useful tank dimensions: LxWxH 450mm*300mm*300mm

- Types of application (dead bath, barrel, vibrating bowl)

This line consists of a treatment line for metal deposits (Zn, Ni, ....) on metal substrates, and an aluminum anodizing line.

Discover the equipment with a video

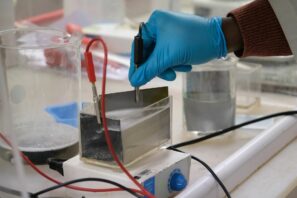

2/ Small pilot line for electroless electroplating/electrolytic deposition

- for A4 parts (rack-mounted) or small parts (barrel-mounted).

- This equipment can be used to produce metallic coatings (Cu, Ni, Ag, Zn, ZnNi, etc.) on the surface of a meltalic object or certain polymers (ABS, PC, etc.).