How do you prepare a sample for SEM analysis?

Problématique

The Scanning Electron Microscope (SEM) is a powerful tool for observing the surface of samples. It provides images with spatial resolution down to the nanometer.

In addition to analyzing surface topography, the SEM can be used to characterize the structure of materials in depth, coatings or multilayers, using cross-sections. In this case, preparation by polishing the surface of the cross-section is crucial.

Some samples are particularly difficult to polish with conventional abrasives, especially in the cases of heterogeneous materials with phases of various hardness. Paradoxically, it is often in the presence of these heterogeneities that the interest of SEM characterization lies.

This case study illustrates how complex samples can be prepared for optimal microscopic observation.

Expertise

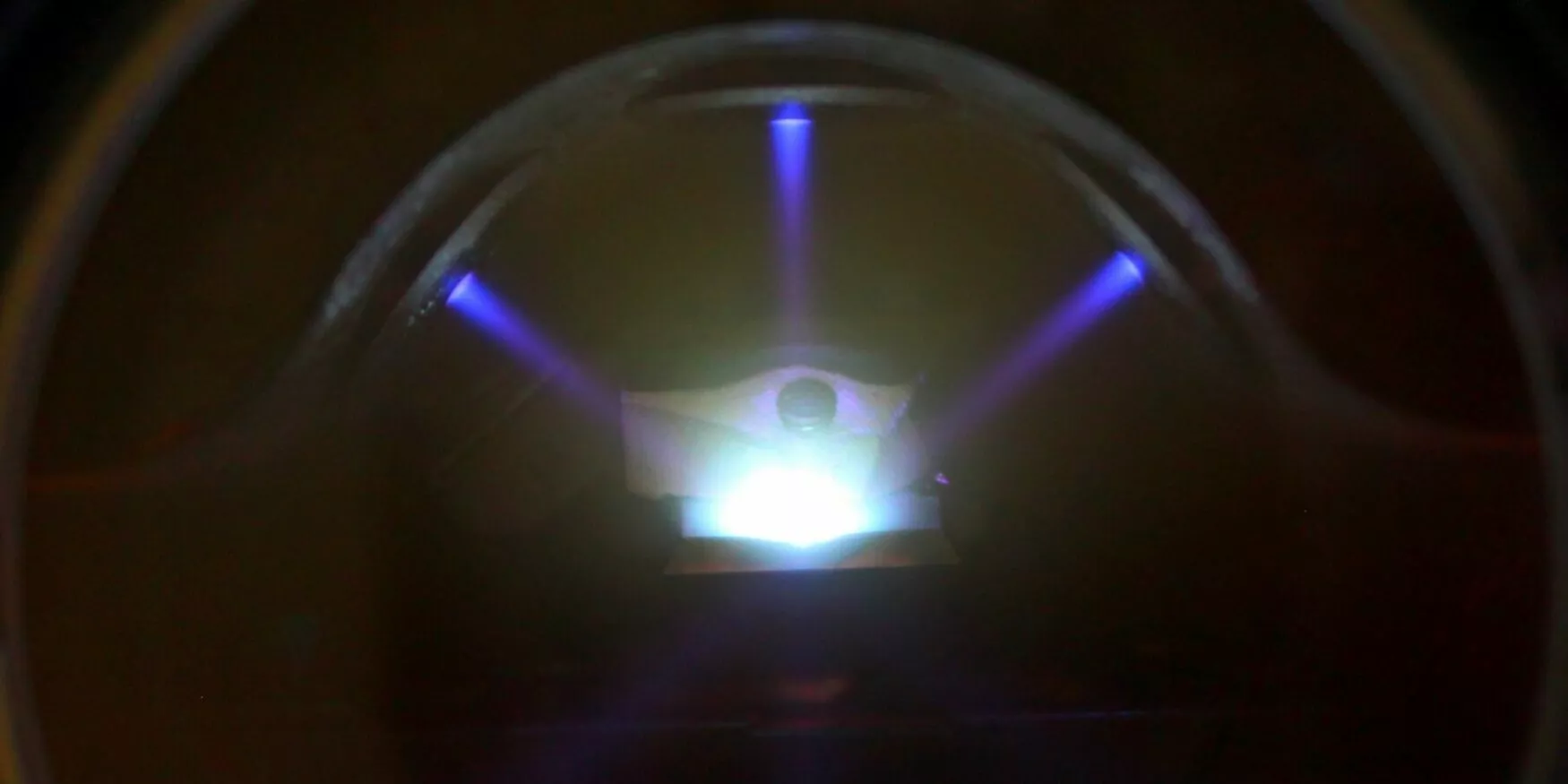

Materia Nova has an ion polisher for polishing heterogeneous samples. It is mainly used prior to scanning electron microscope observations.

Ion polishing enables sample surfaces to be prepared without direct contact, unlike mechanical polishing techniques using abrasives.

Three ion beams remove the material protruding from a mask, leaving a perfectly polished surface. The machine is equipped with a liquid nitrogen cooling system to avoid thermal changes caused by the ions. This technique is mainly used to access the cross-section of materials (composites, wood, textiles, polymers, etc.). It can also be used to visualize very thin layers.

Here are a few examples of samples prepared by ion polishing:

Non-woven textile :

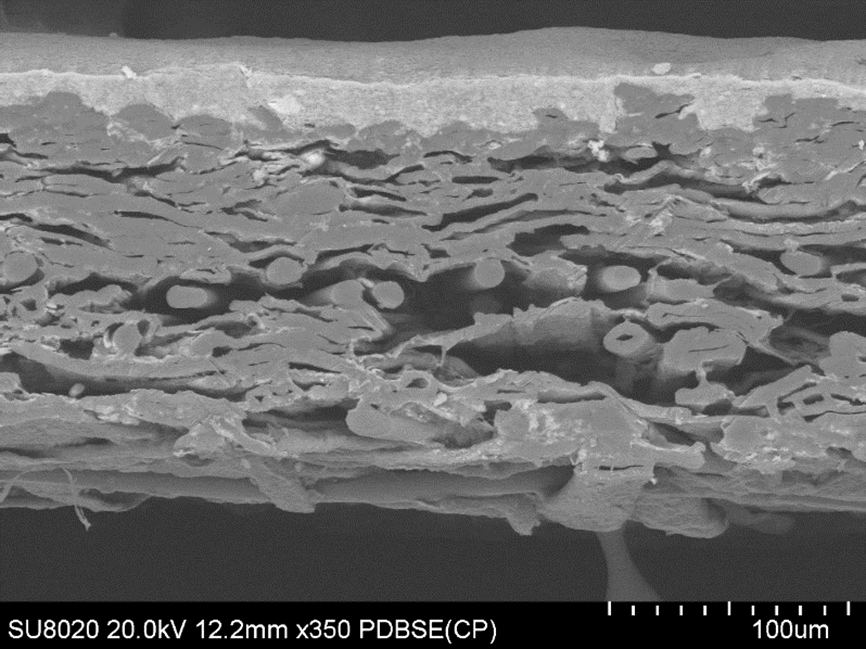

On the sample of non-woven textile below, the cross-section obtained after ion polishing clearly shows the natural (flatter) and synthetic (circular cross-section) fibers, as well as the surface impregnation by the polymer coating..

Cross-section of a polished non-woven textile

Core-shell particle:

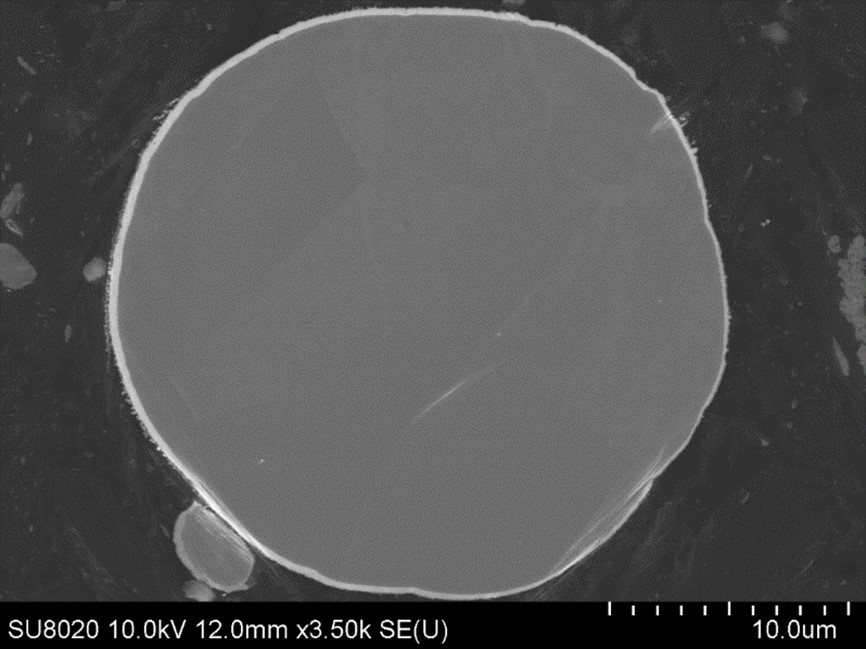

Materia Nova has developed a technique for plasma deposition on powder (ABBEADS). This approach enables powder grains to be coated with a thin layer of metal or alloy. The image below shows how ion polishing can be used to check the homogeneity of a 100 nm-thick layer of silver on a copper particle a few tens of microns thick.

Deposition of a thin layer of silver (100nm) on a powder grain after ion polishing

Multilayer sample :

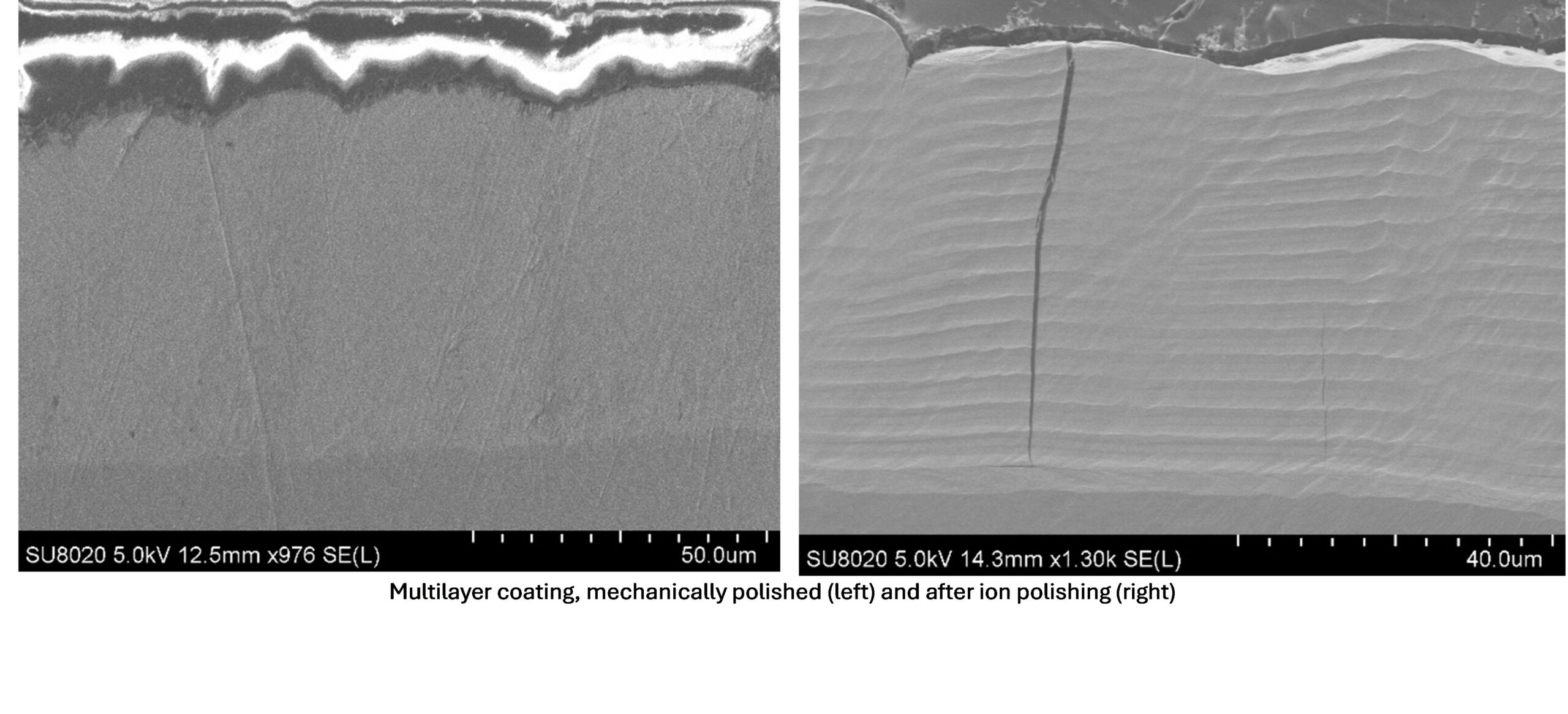

The sample below is a NiW coating obtained by electroplating successive layers. Preparation by conventional polishing (left) does not allow the individual layers to be visualized. However, the interfaces are clearly visible on the cross-section obtained by ion polishing (right).

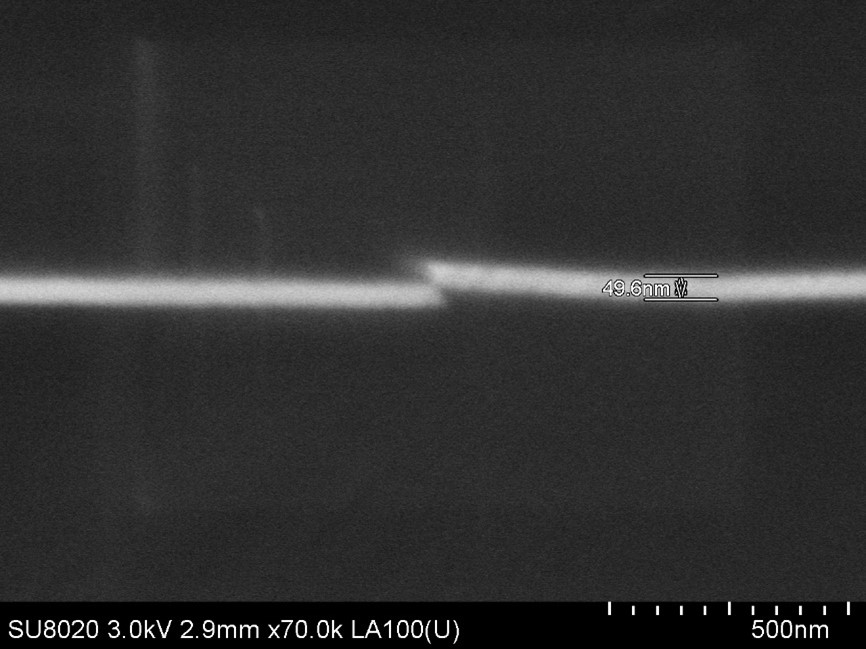

Finally, the sample below consists of a very thin metallic layer (a few tens of nanometers) deposited at the interface between two polymer layers. Here again, preparation of the cross-section by ion polishing enables this layer to be clearly visualized and its thickness (of the order of 49 nm) to be precisely measured.

50 nm thin layer sandwiched between two layers of ionically polished polymer

Solution

The ion polisher enables efficient preparation of cross-sectional samples of all types of solid materials for high quality images under the scanning electron microscope.