How can we characterise the molecular bonds in a conversion layer?

Question

The development of new conversion coatings to protect materials can be hampered by a lack of information about the molecular interactions that are established between the metal substrate and the chemical treatment.

This case study shows how ToF-SIMS is proving to be a highly effective R&D tool for characterising the effective conversion of aluminium after the deposition of a sol-gel coating. In addition, this example illustrates the possibility of evaluating the degree of cross-linking of the deposited layer from the data provided by the mass spectra. This information can be used to understand the performance of a developed solution in terms of corrosion protection.

Expertise

ToF-SIMS is known as a powerful analysis technique providing precise molecular information on the first few nanometres of a material's surface. Thanks to its profiling guns, the equipment available at Materia Nova can also analyse layers several tens of microns thick with nanometric resolution. In this case study, we illustrate the ability of the ToF-SIMS to analyse molecular interactions at the interface between an aluminium substrate and a layer about ten microns thick deposited by sol-gel.

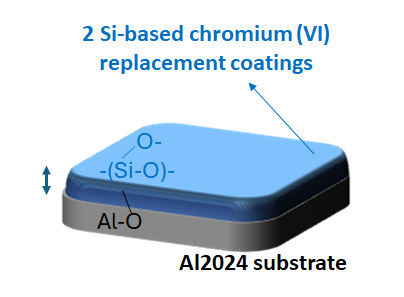

The coatings analysed concerns the development of new conversion layers (chromium VI-free), in particular by our partner Axcentive. Substitution processes still have many limitations and do not always perform as well as expected. Materia Nova has also developed expertise in this field toward its approach to supporting manufacturers in responsible innovation projects.

This study compares the corrosion resistance of aluminium coated with 2 silicon-based coatings (deposited by a sol-gel process) and uses ToF-SIMS to explain the reasons for these differences in performance.

Salt spray tests:

The corrosion resistance of the two sol-gel formulations is assessed using salt spray ageing.

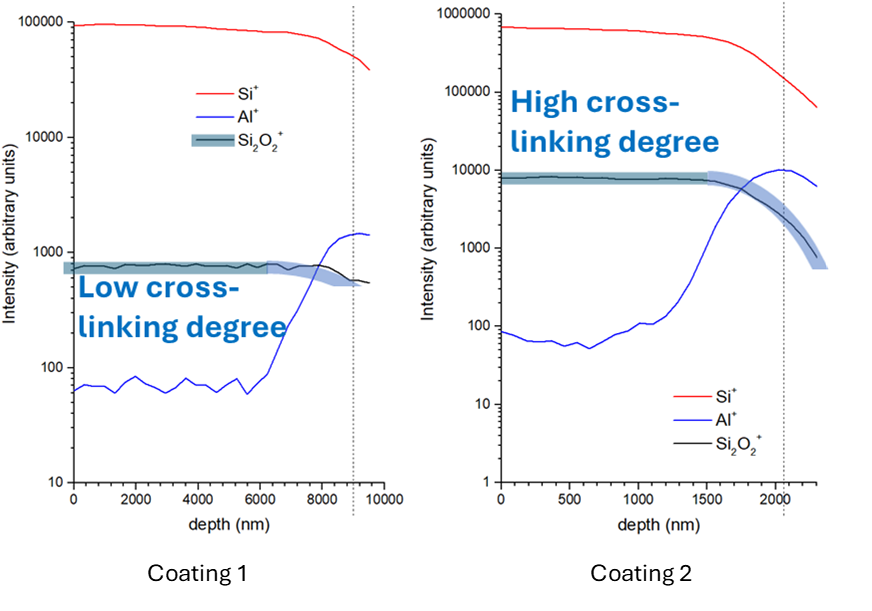

After 300 hours in salt spray, we can clearly see that coating 1 (thickness 2 µm) is quite unaffected, whereas coating 2 (thickness 10 µm) is heavily corroded.

Analysis of the interface by ToF-SIMS:

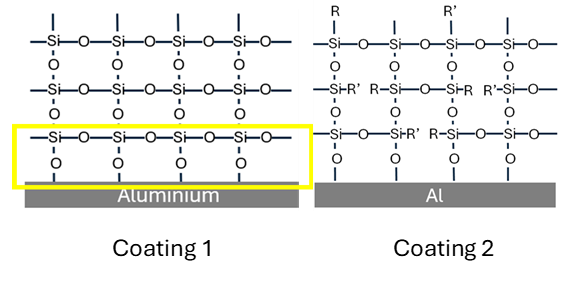

To explain why coating 1 is more resistant, ToF-SIMS profiling analyses are carried out from the surface of the coating to the aluminium substrate. Coating 1 is a pure metal oxide (SiO2); coating 2 additionally contains organic groups (R).

Aluminium conversion can be assessed by tracking the SiOAl+ ion (yellow fluorescent).

- In sample 1, this SiOAl+ ion is mainly present at the interface between the coating and the aluminium substrate (around 1µm). In addition, the Al2OH+ ion is no longer detected, indicating total conversion near the interface.

- In sample 2, the SiOAl+ ion is detected through the entire thickness of the layer, but the signal intensity decreases in the vicinity of the interface with the substrate. In addition, the intensity of the Al2OH+ ion remains constant throughout the layer, revealing a lower conversion in this sample.

Determining the degree of cross-linking :

The degree of cross-linking of the deposited layers can be estimated by tracking the Si2O2+ ion (blue fluorescent). The intensity of this ion is much greater for coating 1, which is therefore the most cross-linked, which explains why it has better barrier properties.

Solution

This study shows that ToF-SIMS is a highly effective tool for characterising conversion layers. Whereas other techniques only provide information about stochiometry of the elements, using ToF-SIMS, molecular species can be identified and their distribution in the thickness of the layer can be determined.

The better anti-corrosion performance of one of the formulations analysed in this study can be explained by 2 fundamental factors that are difficult to access using other techniques:

- better conversion of aluminium to SiOAl+ near the interface,

- better cross-linking density (formation of Si2O2+), optimising the barrier properties of the coating.

This type of investigation is possible on layers of a few tens of µm.

For more information, this study was published in the journal Results in Surfaces and Interfaces (https://doi.org/10.1016/j.rsurfi.2024.100270)