Comparison of corrosion resistance of anodized and sealed aluminum at low temperatures and in boiling water

Question

Is it possible to increase the durability of anodized aluminum other than by conventional sealing with boiling water?

Expertise

Materia Nova has expertise in the development of thin liquid coatings (sol-gel) and in the use of electrochemical techniques to assess the corrosion resistance of anodic layers.

Anodizing is a surface treatment commonly applied to aluminum, titanium, etc. When the material's operating conditions require good chemical and/or corrosion resistance, it is necessary to seal the pores. Often, pore sealing is achieved by immersion in boiling water (an energy-intensive step). To reduce energy consumption, Materia Nova has developed a range of low-temperature, cross-linkable sol-gels for sealing anodized aluminum in sulfuric media. A UV-curable sol-gel solution has been developed, and its performance in terms of corrosion resistance has been compared with that obtained with conventional sealing using boiling water.

The sol-gel process involves the hydrolysis and condensation of a sol composed of silicon alkoxide precursors and a solvent (water, ethanol, etc.). The sol can be applied in various ways: spray, dip-coating, coating, etc. After cross-linking, thin, dense and chemically inert films can be obtained.

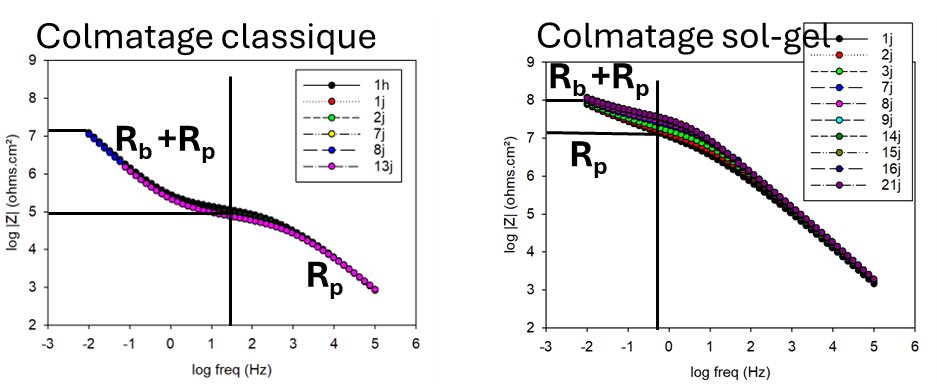

Electrochemical impedance spectroscopy (EIS) was used to assess the corrosion resistance of anodized 1050 aluminum sealed with boiling water or a UV-curable sol-gel.

The EIS technique, which is fast and non-destructive, provides information on the initial barrier properties of the layers, and enables the same sample to be monitored over time. In practice, the metal is brought into contact with a corrosive solution (NaCl 0.5M). A potentiostat is used to superimpose a low-frequency voltage (20mV) on the measured corrosion potential, and to measure the system's current response. The principle of these measurements is detailed in the case study “Evaluation of corrosion resistance of anodized and sealed aluminum”.

The value of the modulus of low-frequency impedance is used to assess the corrosion resistance of a system: the higher the modulus, the greater the corrosion resistance. We can also differentiate between the respective contributions of the barrier and porous layers. In the case of conventional sealing, the overall resistance of the system is around 107 Ohms.cm², rising to 108 Ohms.cm² for sol-gel sealing, a 10-fold increase. In addition, the contribution of the porous layer increases from 105 Ohms.cm² for conventional sealing to 107 Ohms.cm² for sol-gel sealing, an improvement of a factor of 100.

We can also see that the curves evolve little as a function of contact time with the corrosive solution, with protection maintained for up to 21 days.

Solution

Materia Nova developed and applied a UV-curable hybrid sol-gel formulation to anodized aluminum. The results show that the corrosion resistance of anodized aluminum sealed with sol-gel is greater than that obtained by sealing with boiling water. The increased contribution of the porous layer to the overall strength of the system explains the higher corrosion resistance of the sol-gel-impregnated anodic layer compared to that of the boiling water-impregnated layer.