Assessing the effectiveness of flame retardants

Question

How can the effectiveness of new flame retardants be assessed?

Expertise

MATERIA NOVA is very active in improving the fire resistance of materials by optimizing their resistance to ignition, reducing their ability to propagate fire, or reducing heat and smoke release levels. These developments are carried out while preserving the functional properties of the materials, and at an acceptable cost.

Our expertise in this field covers not only the chemical modification of polymers to improve their fire resistance or the development of synergies from commercial flame retardants, but also the design of new flame retardant additives (bio-sourced, for example) or the development of protective surface treatments by dry means (Plasma) or wet (Sol-gel, paints, ...).

MATERIA NOVA has a laboratory dedicated specifically to assessing the fire properties of materials, including Mass Loss Cone Calorimeter, LOI, UL94, smoke chamber and glow-wire testing.

In this case study, one of our customers wishes to evaluate the fire properties (heat release and material mass loss) of a few grams of a new bio-based flame retardant (BioRF) produced in his laboratory.

For a proper evaluation, the first step was to incorporate the flame retardants into polypropylene (PP), a polymer with low fire resistance. MATERIA NOVA produced the PP/BioRF mixtures by melt in an in-house mixer, shaped the sheets by thermocompression, and carried out the fire tests using the Mass Loss Cone Calorimeter (MLC).

Mass Loss Cone Calorimeter

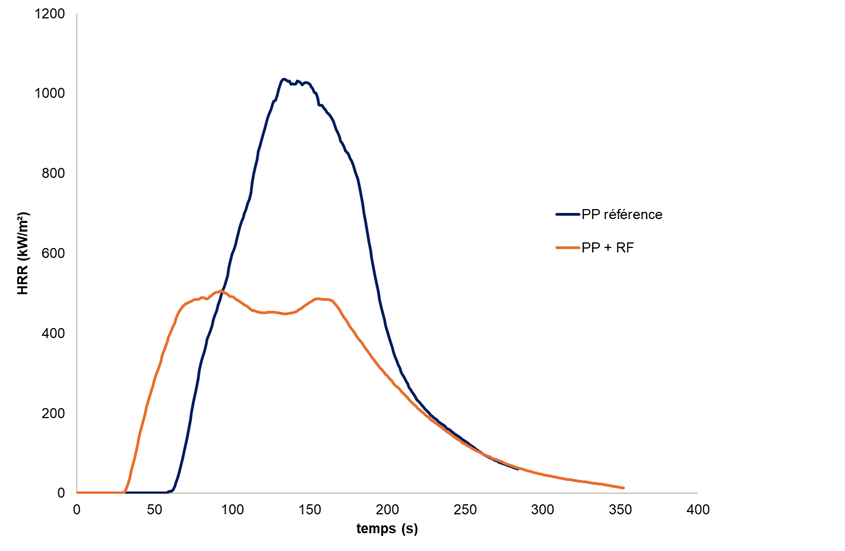

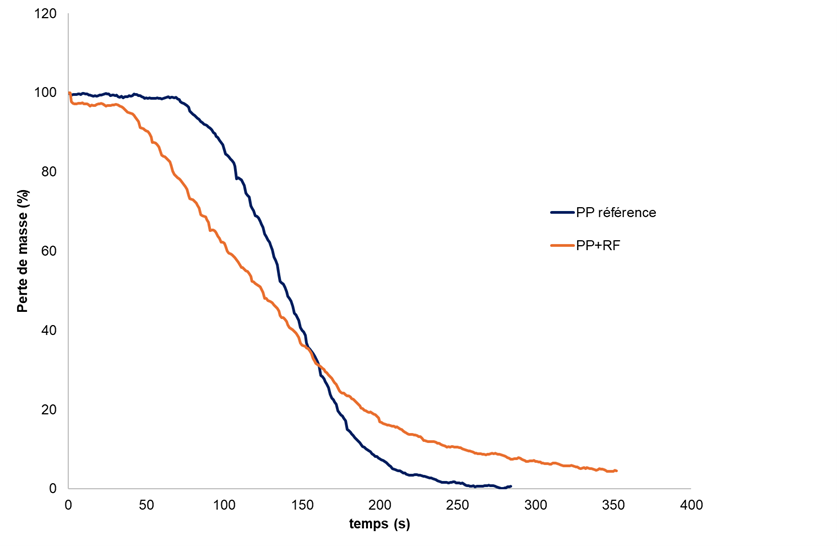

The aim here is to demonstrate the effectiveness of BioRF by assessing the fire behavior of PP+ BioRF composites compared with PP without BioRF. Two indicators are studied:

- HRR (Heat Release Rate), i.e. the amount of heat a material releases per unit area when it burns. This is a fundamental indicator in fire science, as it characterizes the intensity of combustion. A high heat release rate indicates that a material can make a significant contribution to the spread of a fire.

- The material's rate of mass loss, which assesses the rate at which the material is consumed during combustion, over time.

The results obtained highlight two major points. The presence of BioRF induces

- the formation of char during combustion, which limits the release of heat during combustion,

Measurement of heat release rate as a function of time

- a reduction in ignition resistance, as evidenced by a shorter ignition time, induced by premature composite degradation. It is therefore necessary to limit this negative effect by combining this BioRF with other synergistic agents.

Measuring mass loss as a function of time

Solution

These results enabled us to support the customer's investigations and further research.

These tests must be combined with other fire tests such as UL-94, LOI, smoke opacity measurement to characterize other facets of the material's fire behavior.