Accelerated aging

Definition/objectives:

Accelerated aging tests consist in trying to simulate the evolution of a material with or without surface treatment under real conditions, and are absolutely necessary for many industries in order to validate and ensure the properties of products to be marketed.

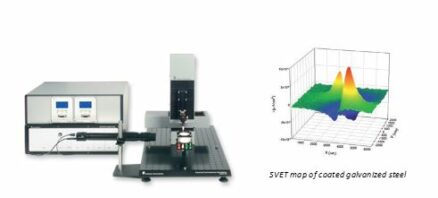

The exposure conditions and cycles are generally adapted and optimized to best represent the real and final conditions of use. Coupled with electrochemical characterization techniques and surface analysis, accelerated aging tests can become rapid tools for system pre-selection.

Performance measurement (standards and equipment tests)

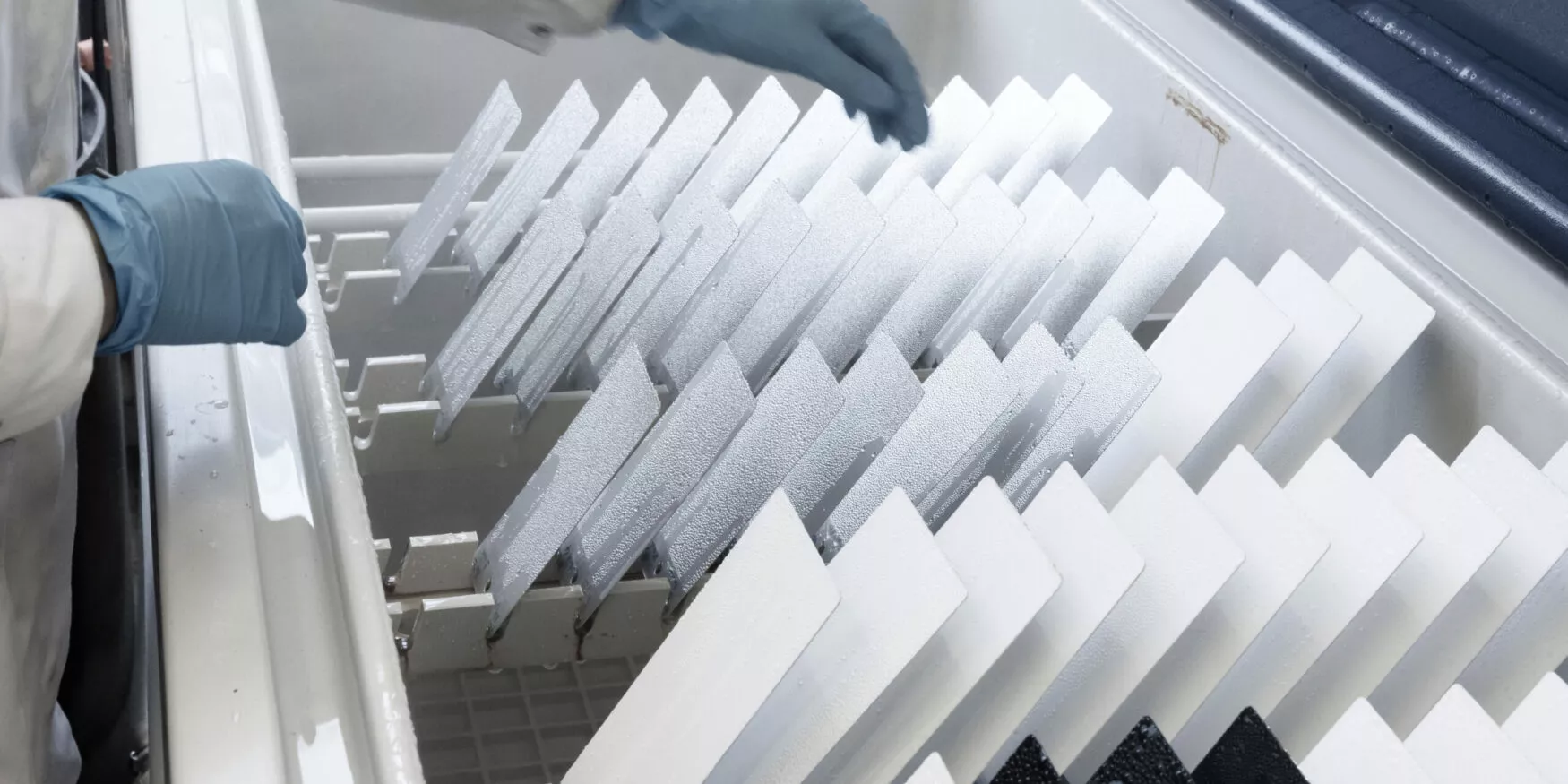

Climatic conditioning tests (salt spray according to ISO 9227 / ASTM B117, humid heat, thermal shock, exposure to condensation humidity ISO 6270, cycle or thermal shock test)

Mechanical fatigue tests (tension, compression, bending, ...) up to 10kN,

Mechanical tests (tubular impact, cylindrical bending, slow drawing),

Photoaging resistance test (QUV chamber according to ISO 11507, Xenon ISO 16474-2)

Adhesion tests (squaring tests according to ISO 2409, evaluation of the blistering rate)

Corrosion study (corrosion expertise

Our strengths

- With significant experience in the study of materials, Materia Nova assists manufacturers in qualifying and improving the aging performance of their products.